E-mail: jonov@jonov.se

SPARE PARTS AND WEAR PARTS

FOR ALL TYPES OF DEMINING MACHINES

We can now offer very high quality wear parts from one of Europe´s leading producers.

Together with our partner, we have the goal to provide the best quality services related to supply of all spare and wear parts, equipment and services needed in Humanitarian Demining and Mine-Clearance operations World Wide, offering the shortest terms of delivery under the best available costs for the end user.

WEAR PARTS:

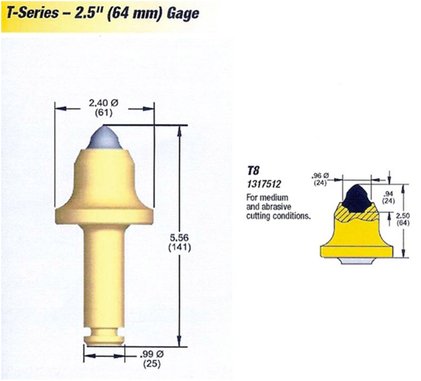

Hammer set

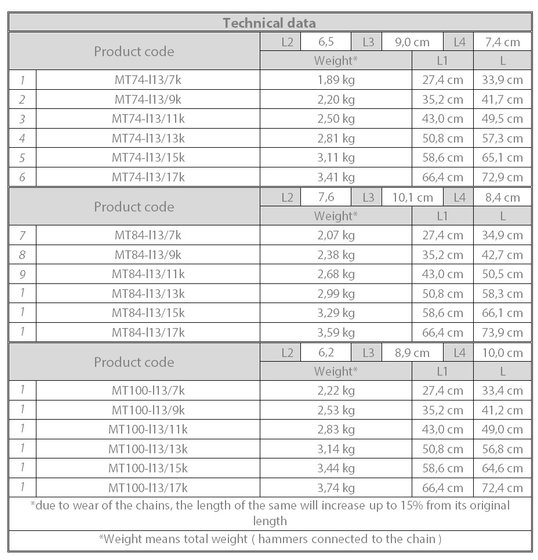

MT74, MT84, MT100

MT hammer set series is classical ‘’mushroom’’ shaped hammer forged from special resistant to wear steel, thermally processed and finalized according to the latest technologies.

MT hammer series are produced in 3 measurement types, thus can easily be installed on all types of machines w/ flail tool.

End result is high digging quality, long- lasting duration, this results in low overall cost per m2.

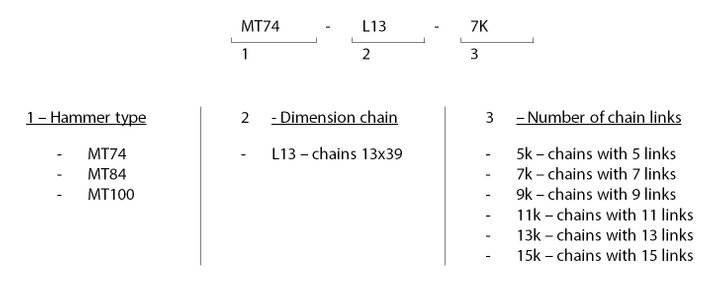

Table displayed below presents the most frequently used chain lengths.

It is important to note that we are able to deliver any other chain length, upon your request.

The best results are achieved on fully loaded shaft at 550-650 rpm.

Chiesel and holder

MT1-10, MT5-EHR, MT-T8,…

We do not produce Chiesels, we purchase them from prominent suppliers, which are recognized by all demining machine manufacturers. Unlike demining machine manufacturers, we offer a variety of different Chiesels, according to type of terrain, providing much lower price.

Weld on holder is our product, produced from borrow steel, which is much more resistant to wear, and better endures welding on rotor, without change in material characteristics.

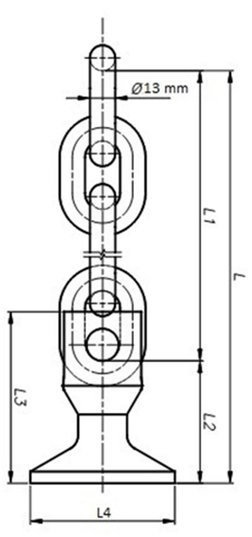

MT1-10

We offer it exclusively. Chiesel designated for the heaviest and hardest terrains w/lot of stone and ground stone. Features Carbid type, which extends the entire length of the Chiesel. Protective pad is ultra resistant to wear, thus providing lifetimeo of Weld on holder.

MT5-EHR

Choice of all demining machine manufacturers. Universal Chiesel suitable for all types of terrain, especially suitable for demining machines which often change type of soil.

MT01

Weld on holder, only in the world produced from boron steel (special type of steel resistant to wear / used in production of padlocks and locks). Features with low price and excellent resistant to wear.

MT5-EHR

Choice of all demining machine manufacturers. Universal Chiesel suitable for all types of terrain, especially suitable for demining machines which often change type of soil.

DEMINING MACHINE FLAIL UNIT SPARE PARTS

A special feature of our hammers, regardless of the shape and purpose, is a particularly well-developed technology of double thermal processing.

The end result is that the outer edge of the bottom part of hammer is extremely hard, so that it keeps its shape and sharpness longer, while the middle and neck parts are softer to obtain optimal toughness and resistance to cracking.

All our hammers are produced from enhanced high-quality tool steel.

With our Hammers set you will renew your flail in record time with just one man. No more on site chains cutting, hammers welding...

Please note that we are capable of supplying you with hammer sets as per your requirements and specifications.

NT96 FORGING OCTONAL DISCS

... specially designed for digging in mixed combination of soil and vegetation with ultimate performance. Suitable for 16x48 chains. Supplied only as a hammer set (hammer attached to a chain)

NTL96 FORGING OCTONAL DISCS

... specially designed for digging in mixed combination of soil and vegetation with ultimate performance. It is very similar to NT96 by design, but is 25% lighter. Suitable for 13x39 chains. Supplied only as a hammer set (hammer attached to a chain)

KD65 FORGING DISCS

... specially designed universal hammer for all type of soil used for vegetation removal demining machine (excavator) with 13x39 chain. Supplied only as a hammer set (hammer attached to a chain)

KD90 FORGING DISCS

... universal hammer for all type of soil used for all sizes of demining machines with 13x39 chain or 16x48 chain. Supplied only as a hammer set (hammer attached to a chain)

KD110 FORGING DISCS

... universal hammer for all type of soil used for all sizes of demining machines where needed better overlaps with 13x39 chain or 16x48 chain. Supplied only as a hammer set (hammer attached to a chain)

FM hammers forged-milling type (FM70, FM90, FM120, FM120/100)

... shaped in a mushroom form. There are 4 basic sizes and weights, suitable for all sizes of demining machines using 13x39 or 16x48 chains. It features great depth of excavation and it enhances durability of the chain. Not advisable to be used for stony soil, specialized for highly erosive soil – sand. It is possible to supply only with a hammer or a hammer set (hammer connected to the chain)

B-4 hammers turn-milling type

...in the form of mushroom; these are our top quality hammers. Hammers in the form of mushroom are designed for all types of soil in all weather conditions. There are two types, for 13x39 chain or 16x48 chain. It is possible to supply only with a hammer or a hammer set (hammer connected to the chain)

B-3 hammers turn-milling type

...in the form of mushrooms for extra small and light demining machine with 13x39 chain. These are our top quality hammers. Hammers in the form of mushroom are designed for all types of soil in all weather conditions. It is possible to supply only with a hammer or a hammer set (hammer connected to the chain)

BS hammers turn-milling type

...in the form of mushroom for extra big and heavy demining machines with 16x48 chain. These are our top quality hammers. Hammers in the form of mushroom are designed for all types of soil in all weather conditions. It is possible to supply only with a hammer or a hammer set (hammer connected to the chain)

SS compact hammer turn-milling type

...in the form of compact hammer, these are our top quality hammers. Hammers in the form of compact hammer are specially designed for stony soil. There are two types, for 13x39 chain or 16x48 chain. It is possible to supply only with a hammer or a hammer set (hammer connected to the chain)

FK forged knives - COMING SOON

... our specially designed tool that replaces classic hammers (disc or mushroom type). It is designed to work in extra strong vegetation and stone free soil. It is possible to supply only with a hammer or a hammer set (hammer connected to the chain)

Connecting accessories

...Bolts, Nuts and Pin Bolts, to connect hammer set to the flail axle, the requested size, socket head or hex head, quality 12.9 or 10.9, for safety and prolonged durability. Safety nut, quality 10

Chains

A special feature of our hammers, regardless of the shape and purpose, is a particularly well-developed technology of double thermal processing.

The end result is that the outer edge of the bottom part of hammer is extremely hard, so that it keeps its shape and sharpness longer, while the middle and neck parts are softer to obtain optimal toughness and resistance to cracking.

All our hammers are produced from enhanced high-quality tool steel.

With our Hammers set you will renew your flail in record time with just one man. No more on site chains cutting, hammers welding...

Please note that we are capable of supplying you with hammer sets as per your requirements and specifications.

...is specially designed for digging in mixed combination of soil and vegetation with ultimate performance. Suitable for 16x48 chains. Supplied only as a hammer set (hammer attached to a chain)

...specially designed universal hammer for all type of soil used for vegetation removal demining machine (excavator) with 13x39 chain. Supplied only as a hammer set (hammer attached to a chain)

...universal hammer for all type of soil used for all sizes of demining machines with 13x39 chain or 16x48 chain. Supplied only as a hammer set (hammer attached to a chain)

...universal hammer for all type of soil used for all sizes of demining machines where needed better overlaps with 13x39 chain or 16x48 chain. Supplied only as a hammer set (hammer attached to a chain)

...it is shaped in a mushroom form. There are 4 basic sizes and weights, suitable for all sizes of demining machines using 13x39 or 16x48 chains. It features great depth of excavation and it enhances durability of the chain. Not advisable to be used for stony soil, specialized for highly erosive soil – sand. It is possible to supply only with a hammer or a hammer set (hammer connected to the chain)

...in the form of mushroom; these are our top quality hammers. Hammers in the form of mushroom are designed for all types of soil in all weather conditions. There are two types, for 13x39 chain or 16x48 chain. It is possible to supply only with a hammer or a hammer set (hammer connected to the chain)

...in the form of mushrooms for extra small and light demining machine with 13x39 chain. These are our top quality hammers. Hammers in the form of mushroom are designed for all types of soil in all weather conditions. It is possible to supply only with a hammer or a hammer set (hammer connected to the chain)

...in the form of mushroom for extra big and heavy demining machines with 16x48 chain. These are our top quality hammers. Hammers in the form of mushroom are designed for all types of soil in all weather conditions. It is possible to supply only with a hammer or a hammer set (hammer connected to the chain)

...in the form of compact hammer, these are our top quality hammers. Hammers in the form of compact hammer are specially designed for stony soil. There are two types, for 13x39 chain or 16x48 chain. It is possible to supply only with a hammer or a hammer set (hammer connected to the chain)

... is our specially designed tool that replaces classic hammers (disc or mushroom type). It is designed to work in extra strong vegetation and stone free soil. It is possible to supply only with a hammer or a hammer set (hammer connected to the chain)

...Bolts, Nuts and Pin Bolts, to connect hammer set to the flail axle, the requested size, socket head or hex head, quality 12.9 or 10.9, for safety and prolonged durability. Safety nut, quality 10

Chains

...we offer standard lifting chains of class 8 quality, as well as the only quality class 10 chains on the market, featuring outstanding durability and high thermal resistance, above the DIN standards from proven German producer. Class 10 chain is blue coated.

DEMINING MACHINE TILLER UNIT SPARE PARTS

(MILLING PICKS AND WELD ON HOLDER)

We offer Milling picks and weld on holder from proven German and US producers only.

Only the best is good enough for our customers.

W1-10 Our best milling picks

Specialized for hard soil conditions and stones. The only milling picks on the market that have an extra long Carbide tip (25 mm), an extra long lasting and with extra strong wear plate for the low tool holder wear.

Packaging in plastic handy toolbox.

W5EHR - Choice of the machine producer

If you want to use exactly the same picks chosen by machine producers, this is milling pick for you.

Packaging in plastic handy toolbox.

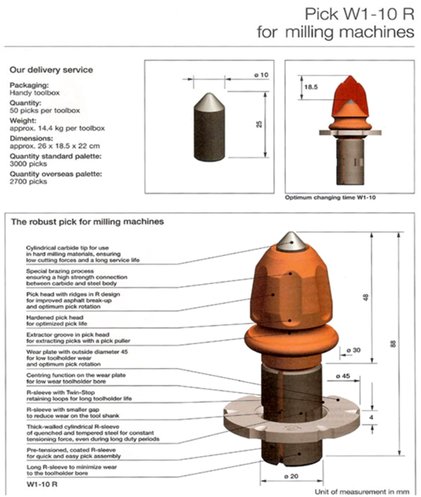

T8 for DIGGER demining machine

Milling picks for Digger demining machine.

...is specially designed for digging in mixed combination of soil and vegetation with ultimate performance. It is very similar to NT96 by design, but is 25% lighter. Suitable for 13x39 chains. Supplied only as a hammer set (hammer attached to a chain)

Weld on holders

Quality weld on holder, choice of all machine producers

Shipment and payment details

Option: We deliver ready-made kits (hammers connected to the chain) or in parts. We also able to offer you, to use chains that you prefer or you can provide.

We are able to produce hammers according to yours specs, demands or technical drawings.

Packaging: All goods are packed in a small carton or plastic box for easier manual loading and unloading, on euro palette. According to your demand, it can be sorted as set or per type.

For resellers we offer a package to your packaging, without our name and logo.

Parity: EXW Zagreb, Croatia or as agreed

Origin of the goods: All our goods are made in EU.

Payment: According to agreement.

Useful info

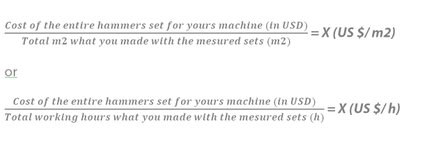

What is the real price of hammer set for Flail demining systems or Chiesel set with holder for tiller?

A great majority of our customers and business partners often ask for the price of hammer sets. The price itself, without any other info cannot present the real picture. The only way to compare price among different producers and suppliers of hammers set is price per m2or price per working hours

(depending how you measure productivity of your demining machine).

Here are the formulas, how the price can be calculated.

Where the X presents price per m2 or w/h in US $ or €.

In order to conclude, when the X in above formula is smaller or decreasing, it means that the hammer set costs you less at the bottom line, meaning you will need less hammers to change. To put as an example, if you work somewhere where transport and storage costs are very high (like Sudan, Angola etc.) your savings are bigger.

There are savings that can also be obtained, but are not covered by this formula- these are referred to decrease in mechanical work (less time needed for replacement of the hammer sets, and a rational use or exchange of nuts, bolts and pins).

What differs our products from the ones from our competitors is that our products are designed to last longer, and the digging quality of the whole set remains constant and proportional until it warns out, meaning that each component of the set has the same lifetime.

Product Code - acronym explanation